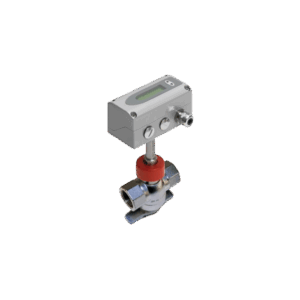

EE680 – Air Velocity & Temperature Sensor

$2,700.00

Instromart brings you the EE680, a high-precision sensor engineered for critical cleanroom applications. Designed for laminar airflow monitoring, it ensures accurate velocity and temperature readings in sterile and controlled environments.

Get Expert Support 1300 000 000

Get expert advice—select with certainty.

The EE680 is a smart sensor specially made to measure how fast air is moving (air velocity) and how warm or cold it is (temperature) — especially in places that need ultra-clean air like pharmaceutical cleanrooms, hospital safety cabinets, or electronics manufacturing.

Technical Specifications:

| Air Velocity Range | 0 to 2 m/s (0 to 400 ft/min) |

| Accuracy (Velocity) | ±(0.5% of reading + 0.05 m/s) |

| Temperature Range | -20°C to +70°C |

| Accuracy (Temperature) | ±0.5°C (when air flow is ≥ 0.45 m/s) |

| Output Options | 4–20 mA, 0–10 V, 0–5 V, RS485 Modbus |

| Response Time | 1.5 seconds (adjustable up to 40s) |

| Power Supply | 24V DC (±20%) |

| Material | High-quality stainless steel |

| Protection | IP65 (dustproof and water splash safe) |

| Mounting | With stainless steel flange (optional) |

| Configuration | Easily done via free software + adapter |

Main Features

Features:

• Very sensitive: Detects even tiny airflows accurately.

• Built for cleanrooms: Follows GMP standards – easy to clean and disinfect.

• Strong protection: Has a special protective coating that stands up to strong disinfectants like hydrogen peroxide (H₂O₂).

• Quick response: Detects changes in airflow and temperature in under 2 seconds.

• Plug-and-play: Easy to install with a stainless steel connector and optional LED ring to show status at a glance.

• Multiple output options: Choose analog signals (voltage/current) or digital communication (RS485 Modbus).

• Two designs: Choose between a straight probe or a 90° angled probe to suit your setup.

Industrial Applications

Industrial Applications:

• Pharma cleanrooms – where medicine is made.

• Laminar airflow cabinets – to protect sensitive experiments.

• Electronics assembly lines – to prevent dust damage.

• Hospital safety cabinets – keeping germs under control.

• HVAC systems – where airflow needs close monitoring.

Reviews

There are no reviews yet.