Main Features

- Comprehensive Measurements: Simultaneously measures water activity (aw), temperature (T), and calculates water content (ppm) in oils.

- High-Temperature and Pressure Tolerance: Operates effectively in oil temperatures up to 180 °C (356 °F) and pressures up to 20 bar (290 psi).

- Versatile Outputs: Offers dual analog outputs (0–1/5/10 V or 0/4–20 mA) and optional digital interfaces (RS485 with Modbus RTU or Ethernet with Modbus TCP).

- Integrated TFT Display: 3.5″ color display provides real-time readings and facilitates configuration and diagnostics.

- Data Logging: Built-in data logger stores up to 20,000 values per measurand, with graphical display and USB download capability.

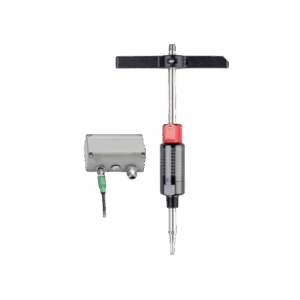

- Flexible Installation: Available with ISO or NPT slide fittings for variable immersion depth; optional ball valve allows probe replacement without process interruption.

- Robust Enclosure: IP65-rated polycarbonate or stainless steel housing ensures durability in harsh environments.

- Easy Configuration: Configurable via display and push buttons or through the free

EE-PCS Product Configuration Software using the USB service interface. - Modular Design: Facilitates easy mounting and maintenance; the upper part housing electronics and probe can be replaced without disturbing wiring.

- Alarm Outputs: Two freely configurable alarm outputs for process control and safety.

- Self-Diagnostics: Extensive error diagnostics displayed on-screen and via status LEDs; audible and visual warnings enhance reliability.

- Pluggable Probe Option: Allows for quick and easy probe replacement, minimizing downtime.

- Power Supply Flexibility: Supports 8–35 V DC or 12–30 V AC; optional 100–240 V AC power supply module available.

- Inspection Certificate: Supplied with a DIN EN 10204-3.1 inspection certificate for verified quality and traceability.

Industrial Applications

- Transformer Oil Monitoring: Prevents dielectric breakdown by detecting moisture levels.

- Hydraulic Oil Monitoring: Identifies water contamination early to maintain system integrity.

- Lubrication Circuits: Protects against corrosion and wear caused by moisture.

- Diesel Fuel Monitoring: Safeguards engines from water-induced damage.

- Predictive Maintenance: Enhances maintenance strategies for hydraulic and rotating machinery.

Reviews

There are no reviews yet.