The Ultimate Industrial Dot Peen Marking System Guide

Traceability is the foundation of quality control. Whether you are producing automotive frames, aerospace fasteners, or oil-field valves, every part needs a permanent “birth certificate.”

The challenge for most facilities is finding a method that balances permanence with cost-efficiency. This industrial dot peen marking system guide serves as a complete resource to help you understand, implement, and master this essential technology.

What is Dot Peen Marking? (The Technology Basics)

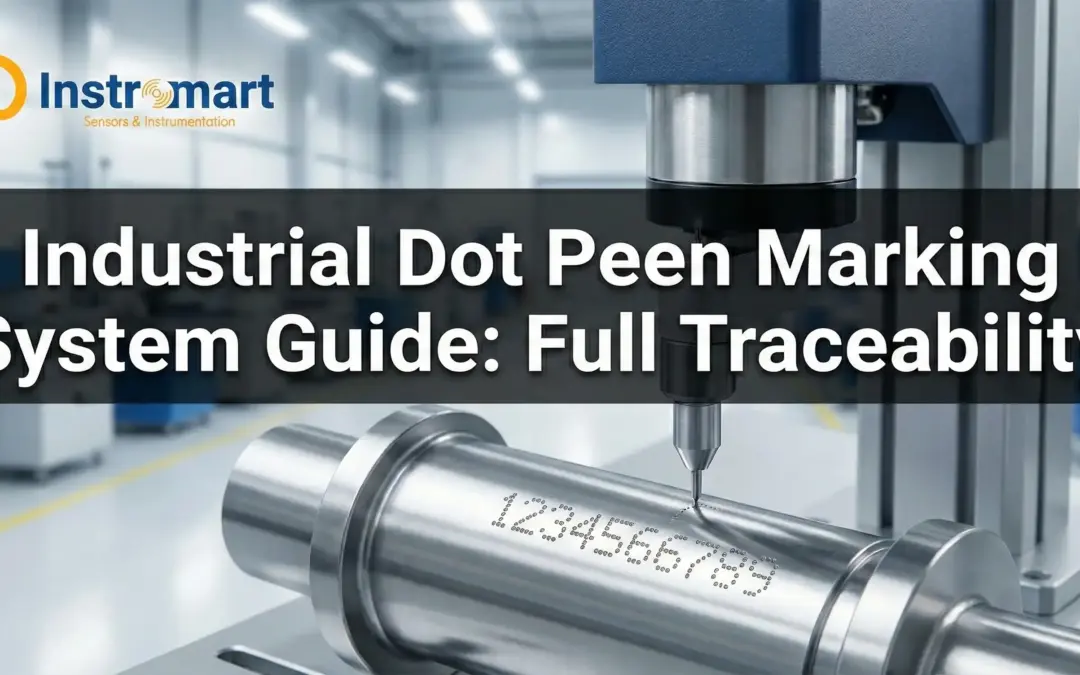

Dot peen marking, often called “pin marking,” is a cold-working process. It uses a hardened carbide or diamond-tipped stylus to strike a material surface thousands of times per second.

The Indentation Mechanism

Unlike laser marking which uses heat, or inkjet which uses chemicals, dot peen uses physical force. Each strike creates a tiny indentation. By precisely controlling the movement of the pin, the system creates text, logos, and 2D Data Matrix codes.

Permanent vs. Temporary Identification

Because the mark is an actual displacement of the metal, it cannot be wiped off or dissolved. This makes it superior for parts that will face extreme heat, sandblasting, or heavy painting cycles.

Core Benefits: Why Use an Industrial Dot Peen System?

This section of our industrial dot peen marking system guide explores the primary reasons why top-tier manufacturers choose this technology over alternatives.

Low Cost of Ownership

The most significant benefit is the lack of consumables. You don’t need ink, ribbons, or gas. Consequently, the only recurring cost is the occasional replacement of the marking pin and electricity.

Material Versatility

Industrial dot peen systems can mark almost any surface—from soft plastics to hardened steel (up to 62-63 HRC). This versatility allows one machine to handle various product lines across a factory.

High-Speed Precision

Modern systems can mark several characters per second. Furthermore, the accuracy of the stepper motors ensures that even the smallest serial numbers are perfectly legible and compliant with ISO/AIM standards.

Choosing the Right Setup: Benchtop vs. Portable

Selecting the right hardware configuration is a critical step in our industrial dot peen marking system guide. Your choice depends entirely on the size and mobility of your parts.

Benchtop Systems (Fixed Stations)

These are ideal for small to medium parts that can be brought to a workstation. They offer the highest level of stability and are often integrated with automated feeding systems for high-volume production.

Portable/Handheld Systems (Field Use)

If you are marking large engine blocks, chassis, or fixed pipelines, you need a handheld unit. Modern cordless, battery-operated markers provide total mobility, allowing you to mark parts anywhere in the yard or on the assembly line.

Advanced Features for Modern Manufacturing

Today’s markers are more than just “hammers.” They are smart devices integrated with your digital factory.

Data Integrity and Software (Industrial Dot Peen Marking System Guide)

A high-quality industrial dot peen marking system guide must highlight the importance of software. Advanced controllers can pull data directly from your SQL database or PLC. This ensures that every serial number is unique and prevents human data-entry errors.

Connectivity and IoT

Modern controllers feature Ethernet, WiFi, and USB ports. Consequently, you can monitor marking progress, update templates, and troubleshoot the machine remotely, which is essential for Industry 4.0 environments.

Frequently Asked Questions (FAQ)

Q: Can dot peen mark through paint?

A: It is highly recommended to mark the bare metal first. While it can mark through thin layers, the mark’s depth is most consistent on raw material. The mark remains visible even after the part is painted later.

Q: How deep can the mark go?

A: Depth depends on the material hardness and the force setting. Typically, depths range from $0.1 \text{ mm}$ to $0.5 \text{ mm}$. Some heavy-duty pneumatic systems can go even deeper for parts that require heavy post-processing.

Q: Is the marking process loud?

A: Since it involves high-frequency mechanical impact, there is noise involved. However, pneumatic systems are generally louder than electromagnetic systems. Most modern markers are well within OSHA safety limits for intermittent noise.

Q: How long does the stylus tip last?

A: Depending on the hardness of the parts you mark, a single carbide tip can last for several thousand marks. Furthermore, the tips can be reground multiple times to extend their life before replacement is necessary.

Conclusion: Making the Right Investment

In summary, an industrial dot peen marking system guide shows that the right technology is about more than just making a mark; it is about securing your data. By choosing a system that offers durability, mobility, and digital connectivity, you protect your company from the risks of untraceable parts.

Investing in a robust dot peen system ensures that your quality control process remains unbreakable, regardless of the harsh environments your products might face.

Need a Personalized Traceability Strategy?

Our team is ready to help you choose the specific marking head, controller, and stylus for your unique application. Let’s make your traceability permanent.

- Browse Industrial Dot Peen Markers

- Contact an Expert for a Demo