In industrial manufacturing, permanent traceability isn’t optional—it’s essential. From automotive components to heavy mining equipment, the right marking solution plays a key role in keeping workflows efficient and reliable.

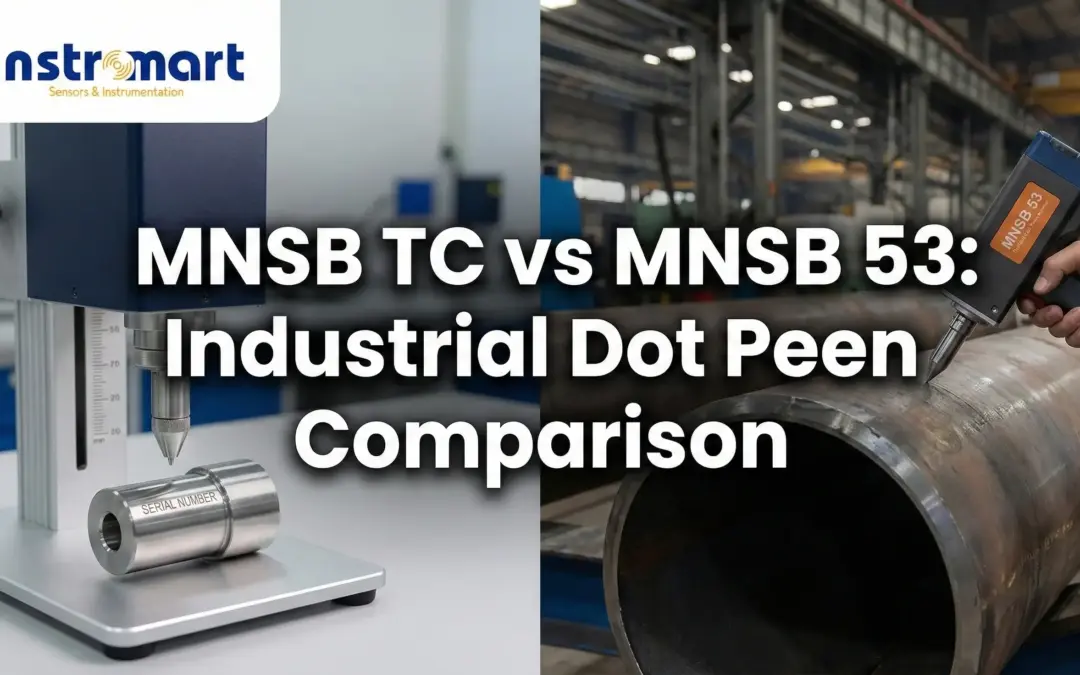

Within the MNSB dot peen range, the MNSB TC and MNSB 53 are two commonly discussed models. Both deliver the durability and performance Instromart is known for, but each is designed to meet different operational requirements.

Understanding the MNSB TC: The Precision Specialist

The MNSB TC is often the go-to choice for workshops requiring a stable, integrated solution. This model typically features an integrated controller, making it a “plug-and-play” powerhouse for stationary marking stations.

- Best for: Small to medium-sized parts that can be brought to a dedicated marking station.

- Key Advantage: High-precision marking with a focus on consistent depth and alignment.

- Integration: Excellent for production lines where the marking process is a fixed step in the assembly.

Understanding the MNSB 53: The Versatile Workhorse

The MNSB 53 is frequently recognized for its balance of power and marking window size. It is often configured as a versatile head that can be adapted for various mounting styles, including portable or benchtop setups.

- Best for: Components that require a larger marking area or more flexible positioning.

- Key advantage: A powerful stylus drive built to handle tougher alloys and create deeper, long-lasting indentations.

- Flexibility: Designed to adapt easily across different industrial settings—from high-volume automotive plants to precision-focused metal fabrication workshops.

Side-by-Side Comparison

|

Feature |

MNSB TC |

MNSB 53 |

|

Primary Setup |

Integrated/Benchtop |

Versatile Head/Portable |

|

Control Unit |

Built-in / Compact |

External Controller Options |

|

Surface Types |

Flat, smooth surfaces |

Flat and slightly curved |

|

Durability |

High (Workshop grade) |

Ultra-High (Industrial grade) |

|

Ideal Application |

Electronics, Small Tools |

Piping, Castings, Heavy Parts |

Which One Should You Choose?

Selecting the right MNSB Dot Peen Machine depends entirely on your floor’s physical layout and the size of your assets:

- Choose the MNSB TC if you have a high volume of small parts and want a compact, all-in-one unit that requires minimal setup space.

- Choose the MNSB 53 if you need more “punch.” If your parts are made of hardened steel or if you anticipate needing to move the marking head to different sections of a large workpiece, the 53 series provides the extra muscle required.

Expert Guidance at Instromart

At Instromart, we specialize in helping businesses achieve 100% traceability with minimal downtime. Both the MNSB TC and MNSB 53 are designed to survive harsh industrial environments, ensuring your serial numbers and barcodes remain legible for the entire lifecycle of the part.